Iyini i-Aluminium Extrusion?

Eminyakeni yamuva nje, i-aluminium extrusion isetshenziswa kabanzi ukwakhiwa kwezimboni nokukhiqiza.Ungase uzwe ngale nqubo yokukhiqiza kodwa donangazi ukuthi isebenza kanjani.Namuhla sizokwenza ube nokuqonda okucacile ngakho nakuba le ndaba.

1. Iyini i-Aluminium Extrusion?

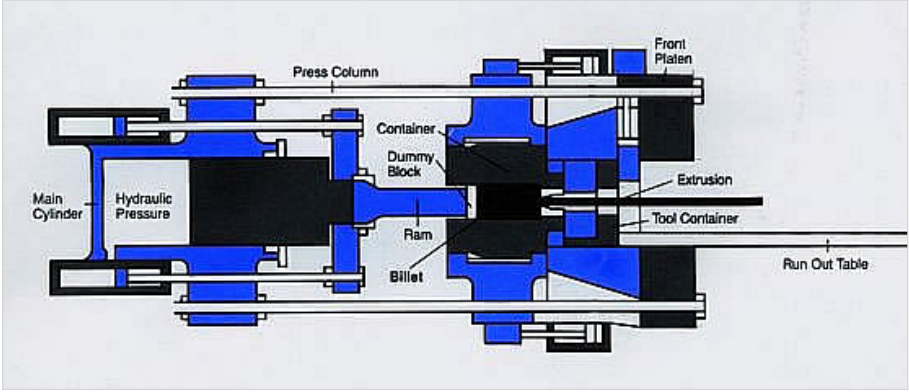

I-Aluminium extrusion iyinqubo lapho impahla ye-aluminium ingxubevange iphoqelelwa ngefa elinephrofayili ethile ye-cross-sectional.Ingafaniswa nokukhama umuthi wokuxubha epayipini.Inqama enamandla iphusha i-aluminiyamu kwidayizi bese iphuma endaweni evulekayo.Uma iphuma, iphuma isesimweni esifanayo nesedayizi futhi ikhishwa eduze kwetafula eligijimayo.

2. I-aluminium extrusion ingasetshenziswa kuphi?

I-Aluminium extrusion ingasetshenziswa kumafayili amaningi, njengamafasitela neminyango yokukhiqiza, ukuklama kwezindonga zamakhethini kanye nokukhiqiza, imoto, amandla aluhlaza, amadivaysi okuxhumana, umshini wasekhaya, ingqalasizinda nokunye.

URui Qifengingahlinzeka ngemikhiqizo ehlukahlukene ye-aluminium extrusion ukuze ibhekane nokusetshenziswa okuhlukile kwamaphrofayili e-aluminium.Sisebenzisana ngqo ne-CHALCO, isandla sokuqala sezinsiza ze-aluminium, sizokunikeza ikhwalithi ephezulu ngamanani avumayo.

Sicela uxhumane nathi ngokuqondile uma unesidingo se-aluminium extrusion.

3. Yiziphi izinqubo ze-aluminium extrusion?

Isinyathelo 1: Umdwebo we-Extrusion die design futhi wenze i-extrusion ife.

Isinyathelo sesi-2: Ukushisa kuqala i-extrusion kufa phakathi kuka-450-500 degrees Celsius futhi kulayishwe emshinini wokunyathelisa we-extrusion.

Isinyathelo sesi-3: Ukushisa kuqala induku ye-aluminium ibe phakathi kuka-400-500 degrees Celsius bese uyidlulisela emshinini wokunyathelisa we-extrusion.I-lubricant (noma i-ejenti yokukhulula) isetshenziswa entweni ye-aluminium kanye nenqama ye-extrusion, ukuvimbela induku ye-aluminium nenqama ekunamathelani ndawonye.

Isinyathelo sesi-4: Iphushela induku ye-aluminium esitsheni bese i-aluminiyamu iphuma endaweni yokuvula idayizi isesimweni sephrofayili eyakheke ngokuphelele.

Isinyathelo sesi-5: Ama-extrusions aqondiswa eduze kwetafula futhi acinywe, noma apholiswe ngokufanayo ngamanzi okugeza noma abalandeli ngaphezu kwetafula.

Isinyathelo sesi-6: Ama-extrusions azogundwa ngesaha elishisayo ukuya kubude betafula ukuze alwehlukanise nenqubo ye-extrusion.

Isinyathelo sesi-7: Ukupholisa i-extrusion ekamelweni lokushisa bese uwahambisa ku-stretcher bese welula ekuqondaneni.Ukwelula kuwukulungisa ukusonteka kwemvelo okwenzeka kumaphrofayili.

Isinyathelo sesi-8: Sika i-extrusion ibe ubude obufanele futhi uze ku-CNC deep-processing.

Isinyathelo sesi-9: Ukuguga ukuya ku-T5 noma T6 ulaka.

Isinyathelo se-10: Ukwelashwa kokushisa nokwelashwa kwendawo.Ukwelashwa kokushisa kungathuthukisa izakhiwo zemishini.Ukwelashwa kwendawo kungathuthukisa ukubukeka nokuvikeleka kokugqwala.Ukwelashwa okungaphezulu kuhlanganisa ukugcotshwa kwempushana, i-anodized, okusanhlamvu kwezinkuni, i-brushed, sandblasting, electrophoresis, polishing kanye ne-PVDF coating nokunye.Sizokwethula ngokwelashwa okungaphezulu endabeni ehlukene.

URui Qifengungumthengisi ochwepheshe ongahlinzeka ngesixazululo samaphrofayili e-aluminium esitobhi esisodwa.Kungakhathaliseki ukuthi yiziphi izidingo kumaphrofayela e-aluminium, kunezinhlobonhlobo zezinketho ongakhetha kuzo ukuze uhlangabezane nezidingo zakho ezicacisiwe kumaphrojekthi.Siyakwamukela ngokuqhubekayouyabuzauma unentshisekelo.

https://www.aluminum-artist.com/

Jenny.xiao@aluminum-artist.com

Isikhathi sokuthumela: Feb-08-2023