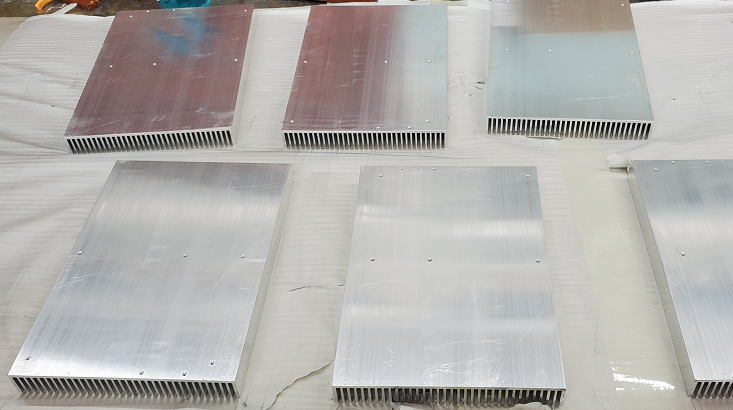

Ama-radiator e-aluminium manje asetshenziswa kabanzi emakethe ye-radiator.Abasebenzisi abaningi bakhetha ukusebenzisa ama-radiator e-aluminium kakhulu nangaphezulu.Kodwa-ke, ngemuva kokuthenga nokufaka ama-radiator e-aluminium, inkinga okufanele icatshangelwe iyeza.Ukungcola kuma-radiator akunakugwenywa, okwenza abasebenzisi abaningi baphathwe yikhanda.Ngakho indlela yokuxazulula le nkinga?Namuhla, i-Ruiqifeng New Material Co., Ltd. izokutshela isisombululo senkinga yokungcola kwe-aluminium radiator!

Okokuqala, sidinga ukwazi imbangela yokwakheka kokungcola kurediyetha ye-aluminium.Ngenxa yokuba khona kwezimbobo zomoya kanye nezimbobo zokushwabana kurediyetha ye-aluminium, ukwelashwa okungaphezulu kwe-die casting kuyinkinga kakhulu.Izimbobo zingase zigcwaliswe ngamanzi, futhi igesi emigodini izoshiswa futhi yandiswe, noma amanzi emigodini azophenduka abe umusi, futhi ivolumu izokhula, okuholela ekuqhumeni ebusweni bokukhishwa.Inkinga yokungcola ijwayelekile futhi ayinakugwenywa.Singakuxazulula kanjani ngemva kokukhiqizwa kokungcola?

1. ukhiye ukunciphisa inani legesi elixutshwe ekubunjweni.Ukugeleza kwe-alloy efanelekile kufanele kusheshiswe ukusuka ku-nozzle kuye emgodini wesikhunta ngokusebenzisa i-shunting cone kanye ne-sprue ukuze kwakhiwe ukugeleza kwensimbi okubushelelezi futhi okungaguquki (umklamo womgijimi we-conical uyamukelwa, okungukuthi, ukugeleza okuthululwayo kufanele kusheshiswe futhi kuncishiswe kancane kancane umlomo wombhobho ku-sprue ukuze kuzuzwe ukugeleza kwensimbi ekahle).

2. ohlelweni lokugcwalisa, igesi ehlanganisiwe ixubene ne-turbulence kanye ne-metal liquid ukwenza ama-pores.Kungabonakala ocwaningweni lwenqubo yokulingisa i-die casting ukuthi uketshezi lwensimbi lungena emgodini wesikhunta lusuka ohlelweni lokuphonsa ukuthi indawo yokuguquka ebukhali ku-sprue kanye nendawo ekhulayo ye-sprue cross-sectional izokwenza uketshezi lwensimbi luphume ku-sprue. isiyaluyalu kanye negesi ye-entrain, kanye noketshezi lwensimbi oluzinzile luhambisana negesi engena emgodini ochichimayo kanye ne-exhaust groove kusukela ku-sprue kanye nesikhunta futhi ikhiphe ngaphandle kwesikhunta.

3. Isihlungi esisha se-ceramic sisetshenziswa esikhundleni se-nozzle yesibili ukuze kuncishiswe ukungcola.Irediyetha ye-aluminium kufanele ipholiswe ngokulinganayo kuzo zonke izindawo phakathi nenqubo yokuqinisa i-diecast futhi iqiniswe ngesikhathi esifanayo.I-shrinkage cavity ingagwenywa ngokuklanywa kwenozzle enengqondo, ukushuba kwesango langaphakathi nendawo, ukwakheka kwesikhunta, ukulawula izinga lokushisa kwesikhunta kanye nokupholisa.

Isikhathi sokuthumela: Jun-28-2022