Kuyini ukwelashwa okungaphezulu kwephrofayili ye-aluminium?

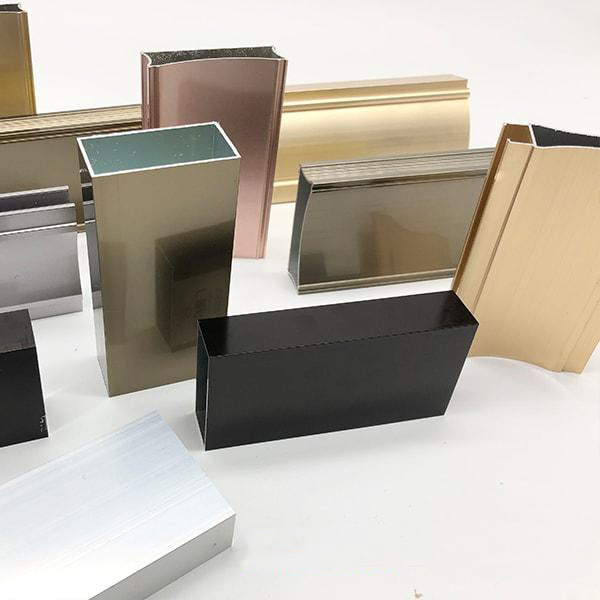

Ukwelashwa okungaphezulu kuqukethe i-coating noma inqubo lapho i-coating isetshenziswa noma ezintweni. Kunezindlela ezihlukahlukene zokwelapha ezitholakalayo ze-aluminium, ngayinye inezinjongo zayo kanye nokusetshenziswa kwayo okungokoqobo, okufana nokuba yinhle kakhudlwana, incamele kangcono, noma ukumelana nokugqwala, njll.

Ngokuthuthuka okuqhubekayo kwamazinga okuphila abantu, izidingo zokubukeka nombala weminyango namafasitela ziya ngokuya ziba phezulu, futhi ngokulungiswa kancane kancane kobuchwepheshe bokucubungula i-aluminium, ezinye izindlela zokwelapha eziyinkimbinkimbi bezilokhu zichuma. Izinqubo zokwelashwa kwe-aluminium ebusweni esivame ukuzibona zifaka i-electrophoresis, i-anodizing, i-powder coating, i-PVDF yokugqoka, okusanhlamvu kwezinkuni nokunye.

1. I-Electrophoresis

I-Electrophoresis iyimbobo ye-electrophoretic ku-cathode ne-anode. Ngaphansi kwesenzo se-voltage, ama-ion e-coating ion ahamba aye ku-cathode futhi ahlanganyele ne-alkalinity ekhiqizwa endaweni ye-cathode ukuze enze izinto ezingancibiliki, ezifakwa phezu kwendawo yokusebenza. I-Aluminium profile electrophoresis ibhekisela enqubweni yokubeka ingxubevange ye-aluminium extruded ethangini le-electrophoresis, nokwenza ifilimu ye-resin ecinene ngaphezulu ngemuva kokudlula kumanje oqondile. Amaphrofayili e-Electrophoretic aluminium akhanya kakhulu futhi anomphumela wesibuko, obuye athuthukise ukumelana nokugqwala.

Ukugeleza Kwenqubo:

I-Electrolysis (ukonakala) ➤ Electrophoresis (ukufuduka, ukufuduka) ➤ Electrodeposition (imvula) ➤ Electroosmosis (ukuphelelwa amanzi emzimbeni)

2. I-Anodizing

Amaphrofayili e-aluminium anodized abhekisela enqubweni lapho i-aluminium nama-alloys ayo akha khona ifilimu ye-oxide emikhiqizweni ye-aluminium (ama-anode) ngaphansi kwe-electrolyte ehambisanayo kanye nezimo zenqubo ethile ngaphansi kwesenzo se-current esetshenzisiwe. Kodwa-ke, ifilimu ye-oxide eyakhiwe phezu kwe-aluminium anodized ihlukile kufilimu ye-oxide evamile, futhi i-aluminium anodized ingadaywa ngombala we-electrolytic. Ukuze unqobe ukukhubazeka kokuqina kobuso be-aluminium ingxubevange, ukumelana nokuguga, njll., ukwandisa ububanzi bokusebenza, futhi andise impilo yesevisi, ubuchwepheshe bokwelashwa kwendawo sebuphenduke isixhumanisi esibalulekile ekusetshenzisweni kwama-alloys e-aluminium, futhi ubuchwepheshe be-anodic oxidation okwamanje busetshenziswa kakhulu futhi buphumelela kakhulu. kwe.

Ukugeleza Kwenqubo:

Ukwehlisa amafutha ➤ Ukucwebeliswa Kwamakhemikhali ➤ Ukugqwala Kwe-Acid ➤ Ukukhumula Ifilimu Emnyama ➤ I-Anodizing ➤ Ukwelashwa Ngaphambi Kokudaya ➤ Ukudaya ➤ Ukuvalwa ➤ Ukomisa

Umehluko phakathi kwe-anodizing ne-electrophoresis: i-anodizing i-oxidized kuqala bese iba nombala, kuyilapho i-electrophoresis inombala oqondile.

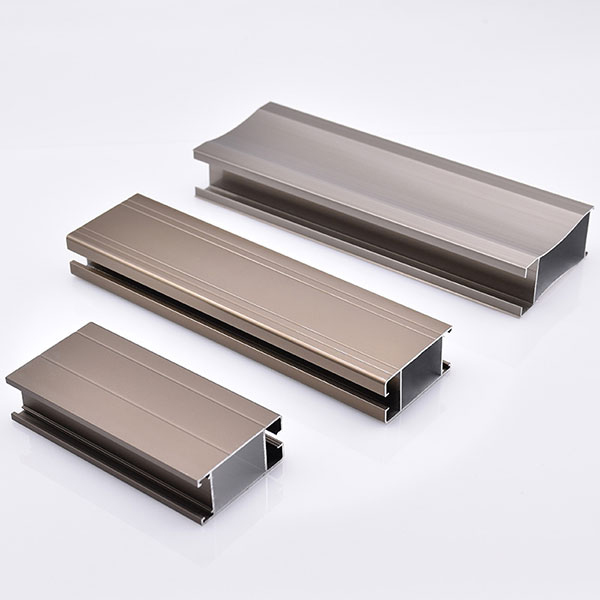

3. I-Powder enamathela

Sebenzisa imishini yokufafaza ngempushana ye-electrostatic ukufafaza i-powder coating ebusweni bomsebenzi wokusebenza. Ngaphansi kwesenzo sikagesi omile, impushana izokhangiswa ngokulinganayo phezu kwendawo yokusebenza ukuze yakhe i-powdery coating. Izingubo zokugcina ezihlukahlukene. Umphumela wokufafaza uphakeme kakhulu kunenqubo yokufafaza ngokwamandla emishini, ukunamathela, ukumelana nokugqwala, nokumelana nokuguga.

Ukugeleza Kwenqubo:

Ukwelashwa kwangaphambili kwendawo ➤ ukufafaza ➤ ukwelapha ukubhaka

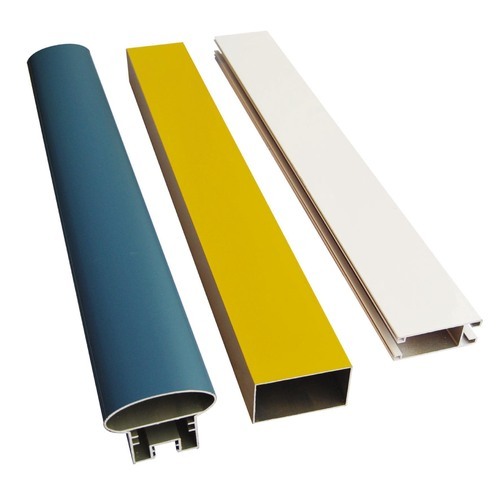

4. I-PVDF Coating

I-PVDF Coating iwuhlobo lokufafaza kwe-electrostatic, okubuye kube yindlela yokufafaza okuwuketshezi. Isifutho se-fluorocarbon esisetshenzisiwe siwukunamathela okwenziwe nge-baking polyvinylidene fluoride resin njengento eyisisekelo noma nge-metal aluminium powder njengombala. Kunezinhlobo ezimisiwe kanye ne-semi-suspended. Uhlobo olumisiwe ukwelapha kwangaphambili kanye nokufuthwa kwezinto ze-aluminium, futhi izinto ze-aluminium ziyamiswa ngesikhathi senqubo yokwelapha. Isembozo sekhwalithi ephezulu ye-fluorocarbon sinokucwebezela kwensimbi, imibala egqamile kanye nomthelela osobala wezinhlangothi ezintathu.

Ukugeleza Kwenqubo:

Inqubo yokwelapha ngaphambi kwesikhathi: ukususwa nokungcoliswa kwe-aluminium ➤ ukuwasha ➤ ukuwasha nge-alkali (ukukhipha amafutha) ➤ ukuwasha ➤ ukugcotshwa ➤ ukuwasha ➤ ukucwenga ➤ ukuwasha ➤ ukuwasha amanzi ahlanzekile

Inqubo yokufafaza: i-primer yokufafaza ➤ topcoat ➤ upende wokuqeda ➤ ukubhaka (180-250℃) ➤ ukuhlolwa kwekhwalithi

Umehluko phakathi kokufafaza kwempushana ye-electrostatic kanye nokufuthwa kwe-fluorocarbon: ukufutha ngempushana ukusebenzisa imishini yokufafaza ngempushana (umshini wokufafaza nge-electrostatic) ukufafaza i-powder coating phezu kwendawo yokusebenza. Ngaphansi kwesenzo sikagesi omile, impushana izokhangiswa ngokulinganayo phezu kwendawo yokusebenza ukuze yakhe isendlalelo sokumboza impushana. Ukufafaza nge-fluorocarbon kuwuhlobo lokufafaza nge-electrostatic, okubuye kube indlela yokufafaza okuwuketshezi. Kubizwa ngokufutha nge-fluorocarbon, futhi kubizwa ngokuthi uwoyela we-curium eHong Kong.

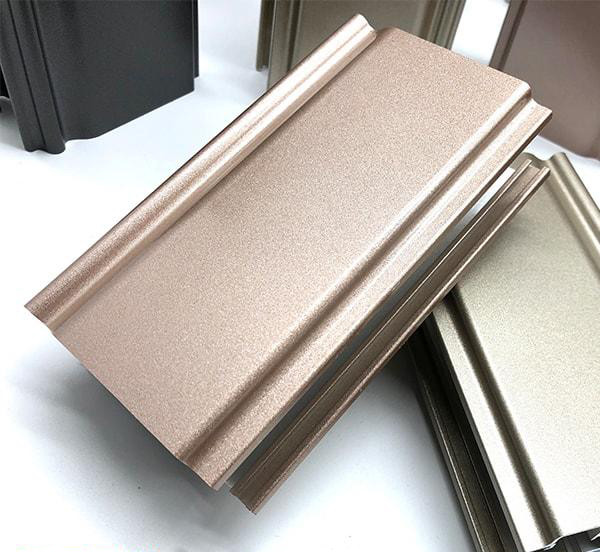

5. Uhlamvu Lwezinkuni

Iphrofayili yokudlulisa okusanhlamvu kwezinkuni isekelwe ekufutheni kwempushana noma umdwebo we-electrophoretic, ngokuvumelana nesimiso sokushisa okuphezulu kwe-sublimation ukungena kokushisa, ngokushisa nokucindezela, iphethini yezinhlamvu zokhuni ephepheni lokudlulisa noma ifilimu yokudlulisa idluliselwa ngokushesha futhi ingene Kumaphrofayili afafaziwe noma i-electrophoresis. Iphrofayili yezinhlamvu zokhuni ekhiqizwayo inokuthungwa okucacile, umphumela onamandla wezinhlangothi ezintathu, futhi ingabonisa kangcono umuzwa wemvelo wokusanhlamvu kwezinkuni. Kuyimpahla efanelekile yokonga amandla kanye nemvelo enobungani esikhundleni sokhuni lwendabuko.

Ukugeleza Kwenqubo:

Khetha ingxenye engaphansi ➤ Goqa iphepha lokuphrinta okusanhlamvu ➤ Isikhwama sepulasitiki sekhava ➤ Vacuum ➤ Ukubhaka ➤ Dabula iphepha lokuphrinta ➤ Hlanza indawo engaphezulu

I-Rui Qifeng ingakwazi ukubhekana nokwelashwa okuyinkimbinkimbi kwendawo yezinto zokwakha. Izinga eliphezulu nezintengo ezifanele, wamukelekile ukuze uthole olunye uphenyo.

I-Guangxi Rui QiFeng New Material Co., Ltd.

Ikheli: Pingguo Industrial Zone, Baise City, Guangxi, China

https://www.aluminum-artist.com/

I-imeyili :Jenny.xiao@aluminum-artist.com

Isikhathi sokuthumela: Feb-20-2023