Ingxenye 2. Ubuchwepheshe: i-aluminium extrusion + i-friction sticker welding njenge-mainstream, i-laser welding kanye ne-FDS noma ibe isiqondiso sesikhathi esizayo

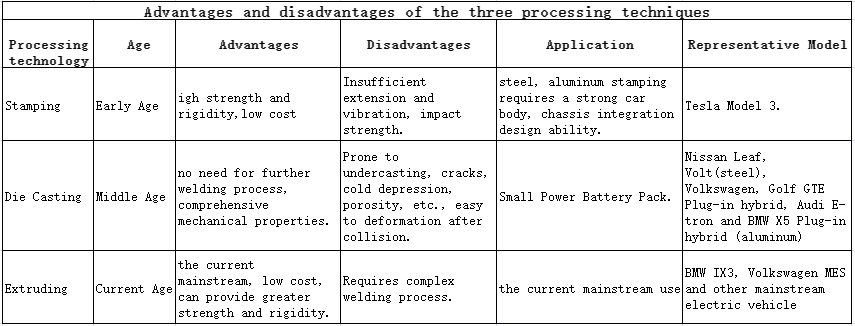

1. Uma kuqhathaniswa ne-die casting kanye nokunyathela, amaphrofayili okwakhiwa kwe-aluminium extrusion kanye nokushisela ubuchwepheshe obujwayelekile bamabhokisi ebhethri okwamanje.

1) Ukujula komdwebo wegobolondo ngaphansi kwephakethe lebhethri elishiselwe ipuleti le-aluminium elinyathelayo, ukudlidliza okunganele namandla okuthinta wephakethe lebhethri, nezinye izinkinga zidinga amabhizinisi ezimoto ukuthi abe nekhono eliqinile lokuklama elihlanganisiwe lomzimba kanye ne-chassis;

2) Ithreyi yebhethri ye-aluminium yokusakazwa kumodi yokusakaza ithatha konke ukubumba kwesikhathi esisodwa. Okubi ukuthi ingxubevange ye-aluminium ijwayele ukwehla, ukuqhekeka, ukuhlukaniswa okubandayo, ukucindezeleka, i-porosity nezinye iziphambeko ohlelweni lokuphonsa. Impahla yokuvala yomkhiqizo ngemva kokuphonswa impofu, futhi ukunwetshwa kwengxube ye-aluminium ekhonjiwe kuphansi, okuthambekele ekuguqukeni ngemva kokushayisana;

3) Ithreyi yebhethri ye-aluminium enwetshiwe iwuhlelo lwamanje olujwayelekile lokuklama ithreyi yebhethri, ngokuhlanganisa nokucutshungulwa kwamaphrofayili ukuze kuhlangatshezwane nezidingo ezihlukene, kunezinzuzo zokuklama okuguquguqukayo, ukucubungula okulula, ukushintshwa okulula nokunye; Ukusebenza Ithreyi yebhethri ye-aluminium enwetshiwe inokuqina okuphezulu, ukumelana nokudlidliza, ukusebenza kwe-extrusion kanye nomthelela.

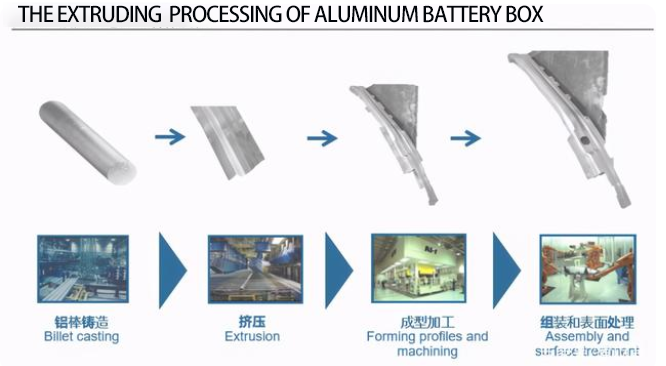

2. Ngokuqondile, inqubo ye-aluminium extrusion ukwakha ibhokisi lebhethri imi kanje:

Ipuleti elingaphansi lomzimba webhokisi lakhiwe ngokushisela i-friction stir welding ngemva kokuthi ibha ye-aluminium isikhishiwe, futhi umzimba webhokisi elingaphansi wakhiwe ngokushisela ngamapuleti aseceleni amane. Njengamanje, iphrofayili ye-aluminium evamile isebenzisa i-6063 noma i-6016 evamile, amandla okuqina aphakathi kuka-220 ~ 240MPa, uma ukusetshenziswa kwamandla aphezulu e-aluminium extruded, amandla aqinile angafinyelela ngaphezu kuka-400MPa, uma kuqhathaniswa nebhokisi lephrofayela ye-aluminium evamile linganciphisa isisindo ngo-20% ~ 30%.

3. Ubuchwepheshe be-Welding bubuye buthuthuke ngokuqhubekayo, okujwayelekile kwamanje ukushisela i-friction stir-welding

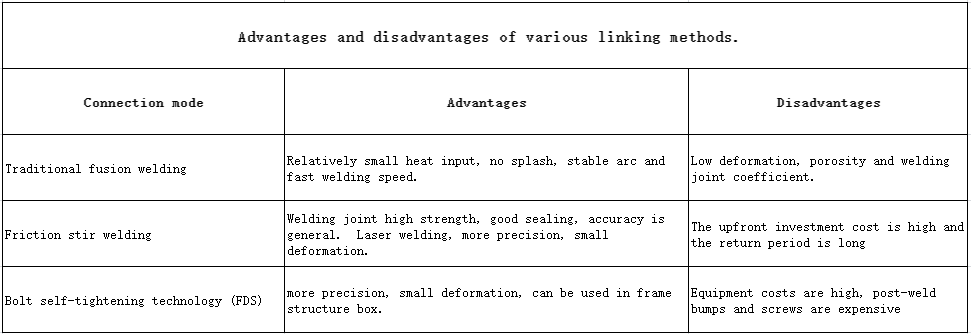

Ngenxa yesidingo sokuhlanganisa iphrofayili, ubuchwepheshe be-welding bunomthelela omkhulu ekucaba nokunemba kwebhokisi lebhethri. Ubuchwepheshe bokushisela ibhokisi lebhethri buhlukaniswe nge-welding yendabuko (i-TIG welding, i-CMT), futhi manje i-mainstream friction welding (FSW), i-laser welding ethuthuke kakhulu, ubuchwepheshe bokuziqinisa (i-FDS) nobuchwepheshe bokubopha.

Ukushisela kwe-TIG kungaphansi kokuvikelwa kwegesi engasebenzi, kusetshenziswa i-arc ekhiqizwe phakathi kwe-tungsten electrode nokushisela ukuze kushise isisekelo sensimbi esincibilikayo futhi sigcwalise ucingo, ukuze kwakheke izinga eliphezulu lokushisela. Kodwa-ke, ngokuvela kwesakhiwo sebhokisi, usayizi webhokisi uba mkhulu, ukwakheka kwephrofayili kuba mncane, futhi ukunemba kobukhulu ngemuva kokushisela kuyathuthukiswa, ukushisela kwe-TIG kusesimweni esingesihle.

I-CMT iyinqubo entsha yokushisela i-MIG/MAG, isebenzisa i-pulse yamanje enkulu ukwenza i-arc yokushisela i-arc kahle, ngokusebenzisa ukungezwani kwendawo ebonakalayo, amandla adonsela phansi kanye nokupompa ngomshini, ukwakha i-weld eqhubekayo, enokufaka okuncane kokushisa, akukho splash, ukuqina kwe-arc kanye nesivinini sokushisela okusheshayo nezinye izinzuzo, zingasetshenziselwa izinto ezihlukahlukene zokushisela. Isibonelo, isakhiwo sebhokisi ngaphansi kwephakheji yebhethri esetshenziswa amamodeli e-BYD ne-BAIC ngokuvamile asebenzisa ubuchwepheshe bokushisela be-CMT.

4. I-fusion welding yendabuko inezinkinga ezifana ne-deformation, i-porosity kanye ne-coefficient ye-welding ephansi ehlangene ebangelwa ukufakwa okukhulu kokushisa. Ngakho-ke, ubuchwepheshe bokushisela obusebenza kahle futhi obuluhlaza obunekhwalithi ephezulu yokushisela busetshenziswe kabanzi.

I-FSW isekelwe ekushiseni okukhiqizwe ukungqubuzana phakathi kwenaliti yokuxuba ejikelezayo kanye nehlombe le-shaft kanye nesisekelo sensimbi njengomthombo wokushisa, ngokuzungezisa inaliti yokuxuba namandla e-axial ehlombe le-shaft ukuze kuzuzwe ukugeleza kwe-plasticization yensimbi eyisisekelo ukuze uthole i-welding joint. Inhlanganisela yokushisela ye-FSW enamandla amakhulu nokusebenza okuhle kokuvala isetshenziswa kabanzi emkhakheni wokushisela ibhokisi lebhethri. Isibonelo, ibhokisi lebhethri lamamodeli amaningi we-Geely ne-Xiaopeng amukela isakhiwo sokushisela esinezinhlangothi ezimbili.

I-laser welding isebenzisa i-laser beam ene-high density yamandla ukuze ikhanyise ingaphezulu lezinto ezizoshiselwa ukuze zincibilikise izinto futhi zakhe ukuhlangana okuthembekile. Imishini yokushisela i-laser ayizange isetshenziswe kabanzi ngenxa yezindleko eziphakeme zokutshalwa kwezimali kokuqala, isikhathi eside sokubuya, kanye nobunzima be-aluminium alloy laser welding.

5. Ukuze kuncishiswe umthelela we-welding deformation ngokunemba kosayizi webhokisi, ubuchwepheshe bokuziqinisa i-bolt (FDS) kanye nobuchwepheshe be-bonding, phakathi kwazo amabhizinisi aziwa kakhulu yi-WEBER eJalimane kanye ne-3M e-United States.

Ubuchwepheshe bokuxhuma i-FDS wuhlobo lwenqubo ebandayo yokwenza isikulufu esizithephayo kanye noxhumano lwebhawodi ngokusebenzisa i-shaft eqinisayo yesikhungo semishini ukuze kuqhutshwe ukujikeleza kwenjini okunesivinini esikhulu ukuze kuxhunywe ekushiseni kwepuleti nokushintshashintsha kwepulasitiki. Ivamise ukusetshenziswa namarobhothi futhi inezinga eliphezulu lokuzishintsha.

Emkhakheni wokukhiqiza iphakethe lebhethri lamandla amasha, inqubo isetshenziswa kakhulu ebhokisini lesakhiwo sefreyimu, nenqubo yokubopha, ukuze kuqinisekiswe amandla okuxhumana anele ngenkathi iqaphela ukusebenza kokuvala kwebhokisi. Isibonelo, ikesi yebhethri yemodeli Yemoto ye-NIO isebenzisa ubuchwepheshe be-FDS futhi ikhiqizwe ngobuningi. Nakuba ubuchwepheshe be-FDS bunezinzuzo ezisobala, bubuye bube nokubi: izindleko eziphezulu zemishini, izindleko eziphezulu ze-post-weld protrusions nezikulufa, njll., nezimo zokusebenza nazo zikhawulela ukusetshenziswa kwayo.

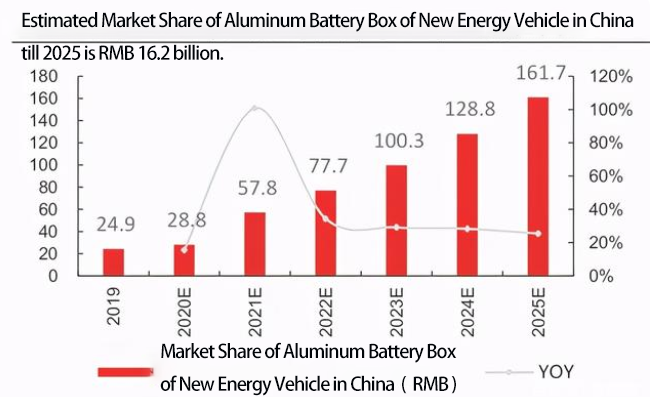

Ingxenye 3. Ukwabelana Ngemakethe: indawo yemakethe yebhokisi lebhethri sikhulu, ngokukhula okuhlanganisiwe okusheshayo

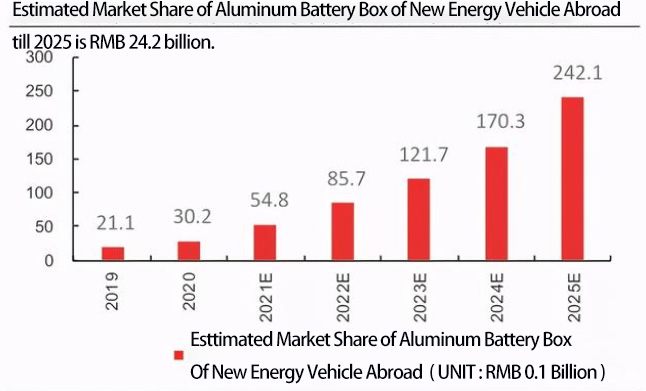

Izimoto zikagesi ezihlanzekile ziyaqhubeka nokukhula ngevolumu, futhi indawo yemakethe yamabhokisi ebhethri ezimoto zamandla amasha sanda ngokushesha. Ngokusekelwe ezilinganisweni zokuthengisa zasekhaya nezasemhlabeni zezimoto zamandla amasha, sibala indawo yemakethe yasekhaya yamabhokisi ebhethri lemoto yamandla amasha ngokuthatha isilinganiso senani ngalinye leyunithi lamabhokisi ebhethri lamandla amasha:

Ukuqagela okubalulekile:

1) Inani lokuthengiswa kwezimoto ezintsha zamandla eChina ngo-2020 liyizigidi eziyi-1.25. Ngokohlelo lwe-Medium and Long-term Development Plan of Automobile Industry olukhishwe yiMinistries kanye namakhomishini amathathu, kunengqondo ukucabanga ukuthi umthamo wokudayiswa kwezimoto ezithwala amandla amasha e-China ngo-2025 uzofinyelela ku-6.34 million, kanti ukukhiqizwa kwezimoto ezintsha ezikhiqiza amandla kuzofinyelela ku-8.07 million.

2) Ivolumu yokuthengisa yasekhaya yezimoto zikagesi ezimsulwa zibalelwa ku-77% ngo-2020, kucatshangwa ukuthi ivolumu yokuthengisa izobalelwa ku-85% ngo-2025.

3) I-permeability yebhokisi lebhethri ye-aluminium alloy kanye nobakaki kugcinwa ku-100%, futhi inani lebhayisikili elilodwa liyi-RMB3000.

Imiphumela yokubala: kulinganiselwa ukuthi ngo-2025, indawo yemakethe yamabhokisi ebhethri ezimoto ezintsha zabagibeli zamandla e-China naphesheya kwezilwandle izoba cishe i-RMB 16.2 billion kanye ne-RMB 24.2 billion, kanti izinga lokukhula elihlanganisiwe kusukela ngo-2020 kuya ku-2025 lizoba ngu-41.2% kanye no-51.7%

Isikhathi sokuthumela: May-16-2022