Imichilo yokubeka uphawu ingenye yezesekeli ezibaluleke kakhulu zomnyango namafasitela. Zisetshenziswa ikakhulukazi kuma-frame sashes, ingilazi yefreyimu nezinye izingxenye. Badlala indima yokuvala, ukuvimbela amanzi, ukuvala umsindo, ukumunca ukushaqeka, nokugcina ukushisa. Kudingeka ukuthi babe namandla okuhle okuqina, ukunwebeka, ukumelana nezinga lokushisa kanye nokumelana nokuguga.

Imichilo yokuvala kanye namaphrofayili kuhlanganiswe ukuze kuzuzwe ukusebenza kokuvalwa okudingekayo, okuthintekayo ngezinto eziyinhloko, indlela yokufaka, ububanzi bokusebenza kokucindezelwa, amandla okucindezela kanye nokuma kwe-cross-sectional of the strips.

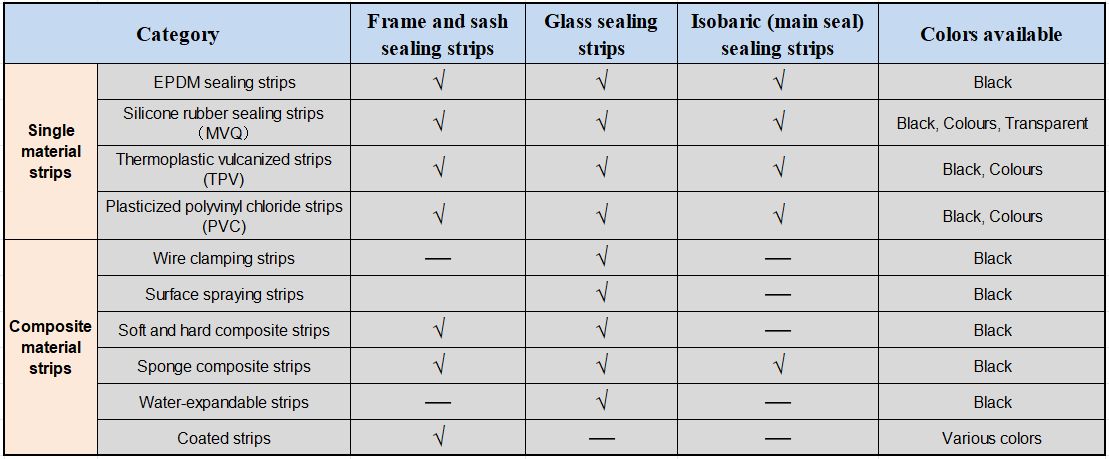

Imichilo yokuvala ingahlukaniswa ibe yimichilo yempahla eyodwa kanye namapheshana ezinto ezihlanganisiwe ngokuya ngempahla.

Imichilo yempahla eyodwa ikakhulukazi ihlanganisa imichilo yokuvala ye-EPDM, imicu yokuvala irabha ye-silicone (MVQ), imichilo ye-thermoplastic vulcanized (TPV), kanye nemichilo ye-polyvinyl chloride (PVC). Imichilo yempahla eyinhlanganisela ikakhulukazi ihlanganisa imichilo yocingo, imichilo yesifutho esingaphezulu, imicu eyinhlanganisela ethambile neqinile, imicu eyinhlanganisela yesipontshi, imichilo enwebeka ngamanzi, nemicu eboshwe.

Izimo ezisebenzayo zezinhlobo ezahlukene zemicu yokuvala evame ukusetshenziswa ikhonjisiwe kuthebula elingezansi.

Imichilo yokuvalwa kwe-EPDM inezinto ezinhle kakhulu eziyisisekelo eziyisisekelo (amandla okudonsa, ubude ngesikhathi sekhefu, kanye nokuguqulwa okuhlala njalo kokucindezelwa), ukumelana nesimo sezulu okuvelele, ukumelana nezinga lokushisa eliphezulu neliphansi, ukumelana nokugqwala, nokusebenza okuhle kakhulu okuphelele. Njengamanje zisetshenziswa kabanzi emkhakheni weminyango namafasitela.

Ibanga lokushisa elinconywayo elisebenzayo lemicu evamile yokuvala: Impahla ye-EPDM ingu -60℃~150℃, impahla ye-MVQ ingu -60℃~300℃, impahla ye-TPV ingu -40℃~150℃, kanti impahla ye-PVC ingu -25℃~70℃.

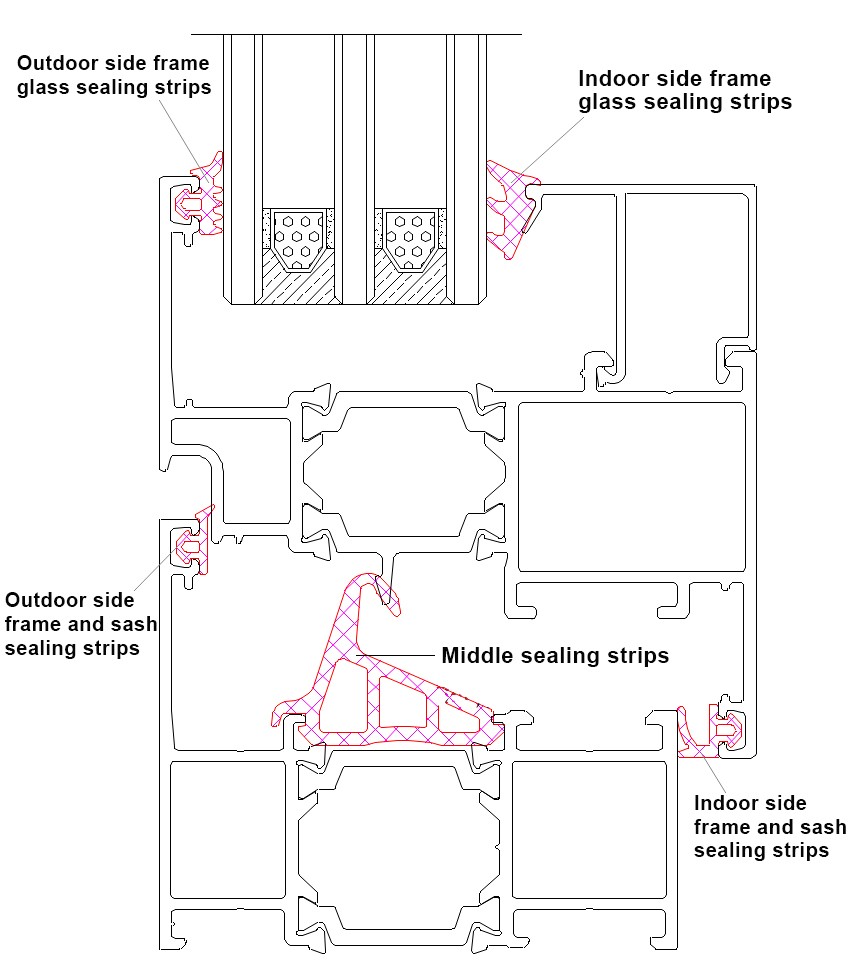

Imichilo yokuvala ingahlukaniswa ngohlobo lokucindezelwa, uhlobo lokungena, kanye nohlobo lokunamathela ngokuya ngendlela yokufaka. Angahlukaniswa abe yimichilo yokuvala i-frame-sash, imichilo yokuvala ingilazi yefreyimu, kanye nemichilo yokuvala emaphakathi ngokuya ngendawo yokufakwa kwezicabha namafasitela.

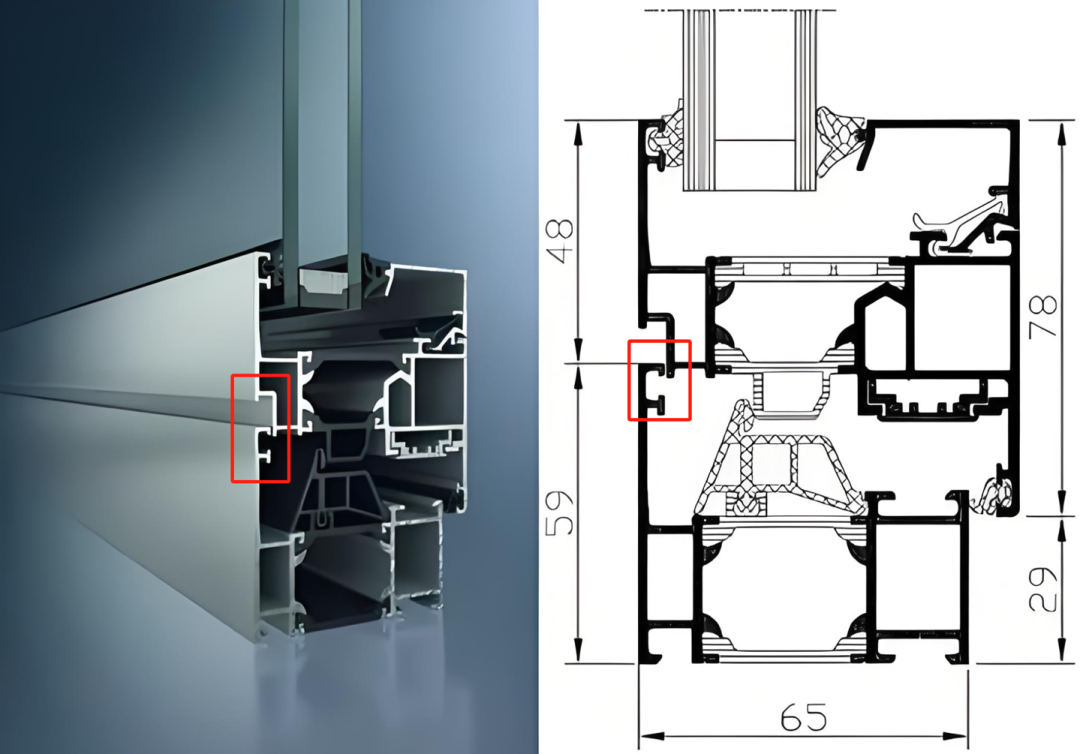

I-frame-sash node yomnyango ophukile we-aluminium alloy kanye nefasitela kukhonjisiwe esithombeni esingezansi.

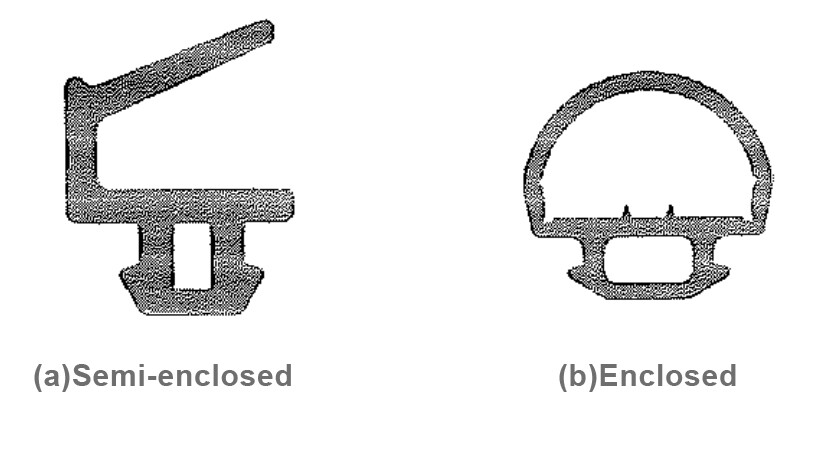

Umumo we-cross-sectional we-frame-sash sealing strip kufanele ukhethwe njenge-semi-evaleleke noma evalelwe ngokuvumelana nezidingo. Uma umklamo odingekayo unobubanzi obukhulu bokusebenza noma izidingo zokusebenza zokuvala uphawu, kufanele kukhethwe isakhiwo esivalekile.

Indlela yokufaka yomugqa wokuvala phakathi kwefreyimu nesashi kufanele kube ukufakwa okulingana nokucindezela. Idizayini yesayizi yengxenye yokufaka yomugqa kufanele iqinisekise ukuthi ayiwi futhi ilingana ngokuqinile ne-groove yephrofayili.

Umucu wokuvala phakathi kohlaka nesashi ubuye ubizwe ngokuthi umucu wokuvala oyinhloko noma umucu wokuvala we-isobaric. Idlala indima yokuvimbela i-air convection kanye nemisebe yokushisa kuphrofayela. Kufanele ihlangabezane nezidingo zombili zokuvala kanye nezidingo zamandla okuvula nokuvala eminyango namafasitela.

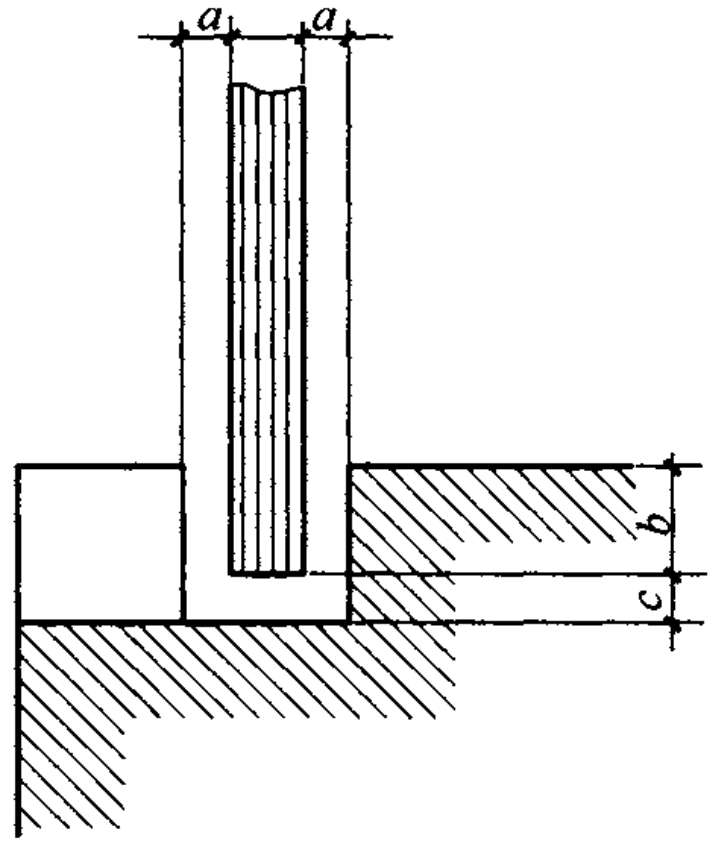

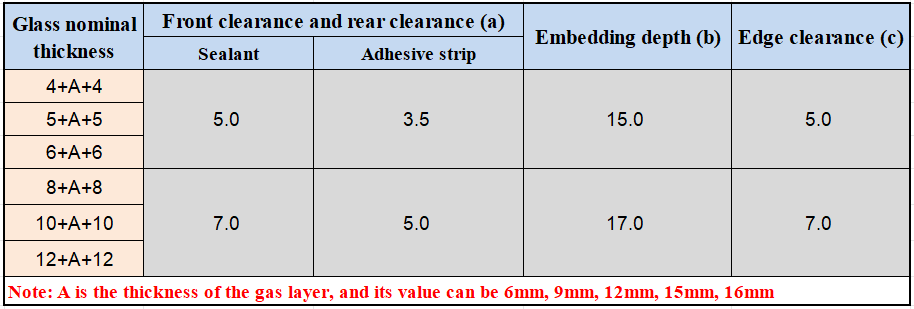

Izidingo zosayizi wesikhala sokufaka zomugqa wokuvala phakathi kohlaka nengilazi zivezwe kokuthi JGJ 113-2015 “Ikhodi Yobuchwepheshe Yokusetshenziswa Kwengilazi Yokwakha”, bheka ithebula elingezansi.

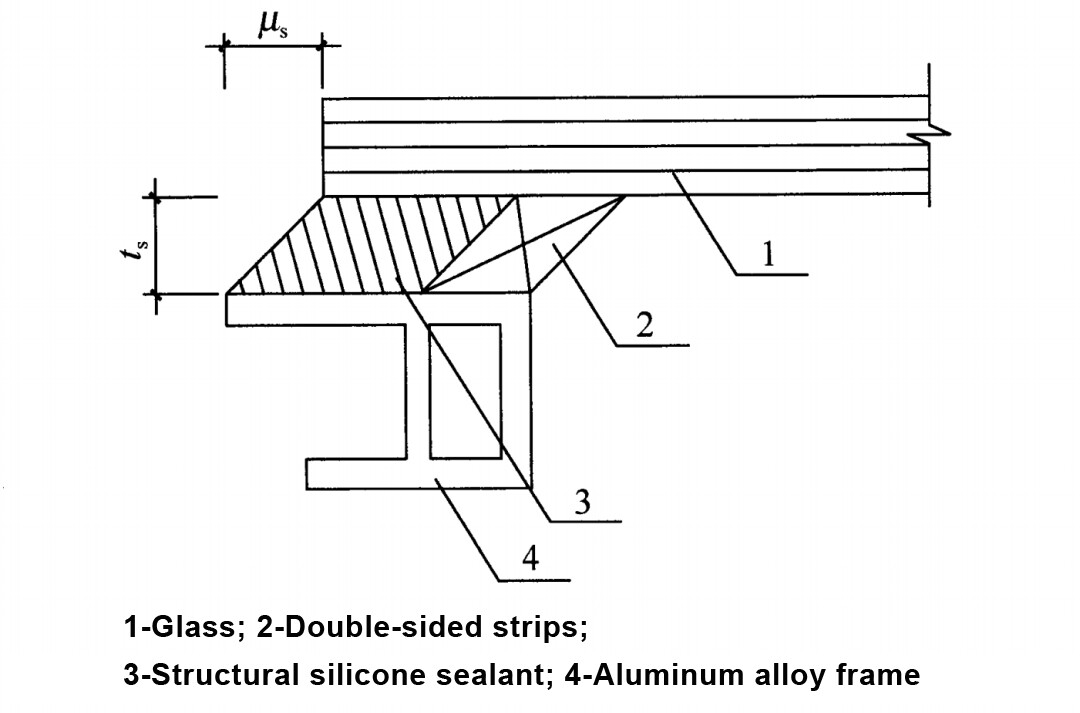

Phakathi kwazo, ubukhulu be-a, b, kanye no-c buboniswa esithombeni esingezansi.

Izimo ezivamile ze-cross-sectional zomugqa wokuvala phakathi kohlaka nengilazi ziboniswa esithombeni esingezansi, futhi indlela yokufaka i-press-fit yokufaka ivame ukwamukelwa.

Ekhuluma ngomugqa wokubeka uphawu phakathi kohlaka nengilazi, kunomunye umbuzo okufanele uxoxwe ngawo, okungukuthi, kungcono yini ukusebenzisa imichilo yokuvala noma ama-sealants phakathi kohlaka nengilazi?

Njengamanje, izinkampani eziningi zesistimu yeminyango namafasitela ekhaya nakwamanye amazwe zisebenzisa amapheshana njengenketho yokuqala yokuvala ingilazi yohlaka. Lokhu kungenxa yokuthi umugqa werabha uwumkhiqizo owenziwe ngezimboni, ikhwalithi yokufaka iyalawuleka, futhi kulula ukushintshwa.

Mayelana nokusebenza kokufaka uphawu, nakuba i-JGJ 113-2015 “Ikhodi Yobuchwepheshe Yokusetshenziswa Kwengilazi Yokwakha” inikeza imithethonqubo yokuvula indawo yangaphambili nengemuva, okulingana nokugunyaza le ndlela, ayikanconywa ukwenza kanjalo esizeni ngenxa yalezi zizathu ezilandelayo:

Ikhwalithi yokufaka i-sealant esizeni ayilawuleki, ikakhulukazi ukujula kokufakwa kwe-sealant.

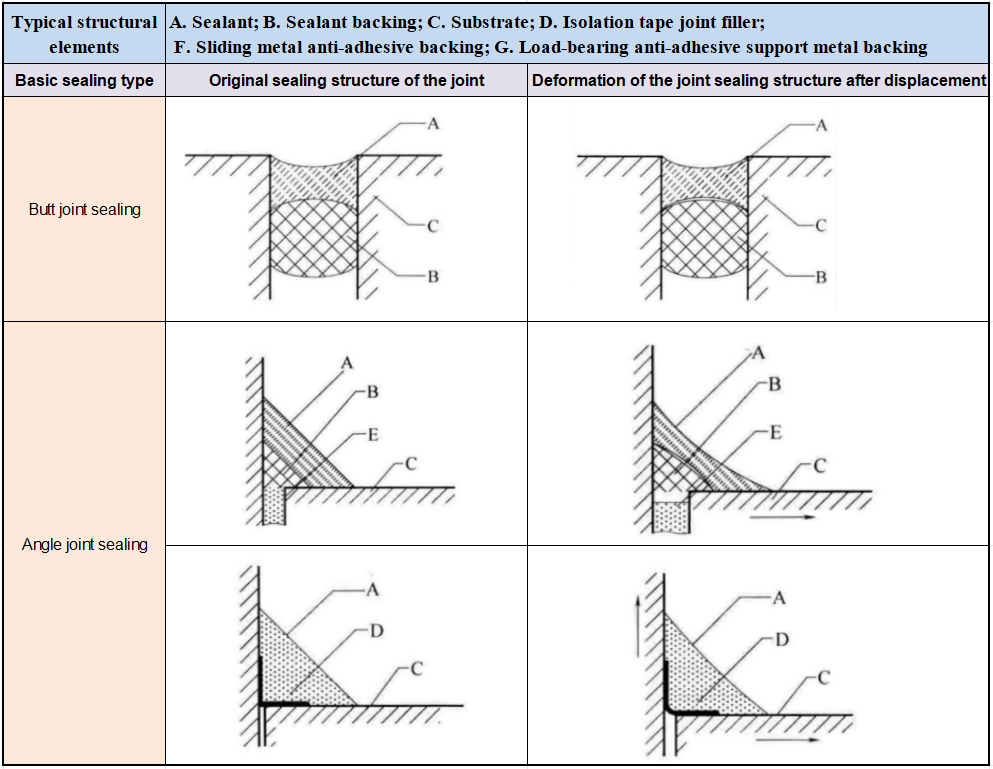

I-T/CECS 581-2019 “Ikhodi Yobuchwepheshe Yokusebenzisa I-Building Joint Sealant” inikeza amafomu nezakhiwo eziyisisekelo zokuvala ngokuhlanganyela, bheka ithebula elingezansi.

Kungabonakala ukuthi izinyathelo ezihambisanayo zidinga ukuthathwa ukuze kulawulwe ikhwalithi yokwakha yokuvala amalunga ezinqe kanye nokuhlangana kwemigwaqo.

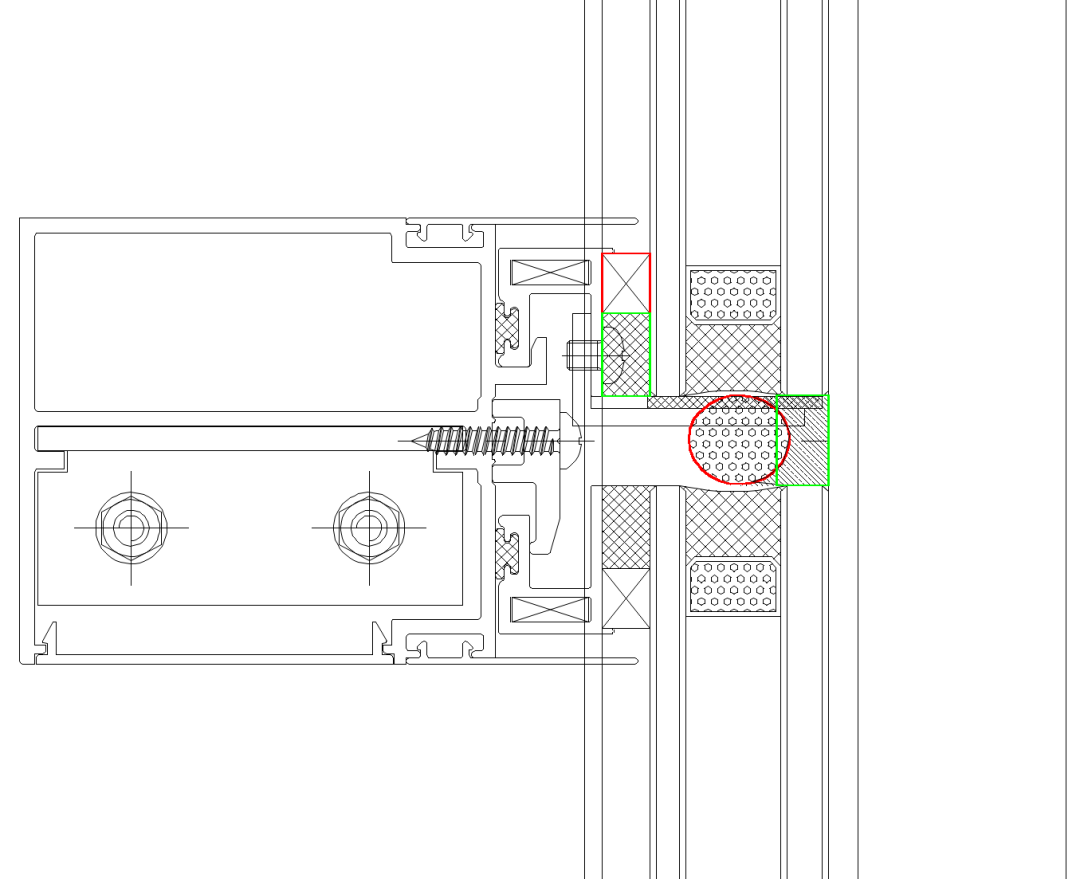

Isibonelo, ijoyinti yokuvala yangaphandle yodonga lwekhethini yengilazi yefreyimu evamile iyinhlanganisela yokuvala izinqe, futhi ikhwalithi yokwakha ilawulwa yinduku yegwebu. Ingilazi kanye nefreyimu enamathiselwe kuboshwe izitika ezinezinhlangothi ezimbili ukuze zilawule ububanzi nogqinsi lwe-adhesive yesakhiwo, njengoba kukhonjisiwe esithombeni esingezansi.

Amaphrofayili ezingxenye zokufakwa kwamafasitela e-aluminium alloy kanye nengilazi yefasitela yepulasitiki wonke amaphrofayili anezindonga ezincane - ubuhlalu bengilazi, ingalo yephrofayili eseceleni yangaphandle, njll., futhi ayinayo imibandela yokulawula ububanzi nokuqina kwe-sealant.

Ngaphezu kwalokho, ukusebenzisa i-sealant yangaphandle ngemuva kokufaka ingilazi kuyingozi kakhulu. Iningi lokufakwa kweminyango namafasitela kuqedwa ngaphakathi endlini, kuyilapho isivalo sangaphandle sidinga ukufakwa ngaphandle. Kuyingozi uma ingekho inkundla yokusebenza yangaphandle njenge-scaffolding, obhasikidi abalengayo, namaloli ama-boom, ikakhulukazi uma amaphaneli engilazi emakhulu.

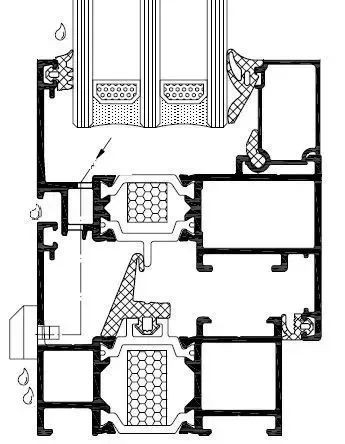

Enye inkinga evamile ukuthi izindawo eziningi zesistimu yezicabha namafasitela zaseYurophu azinawo amafreyimu angaphandle asemaceleni nemicu yokuvala ibhande, njengoba kukhonjisiwe esithombeni esingezansi.

Lo mklamo awukona ukusika amakhona kodwa ukucatshangelwa kwe-drainage.

Izicabha namafasitela azoba nezimbobo zokudonsa amanzi kuhlaka oluvundlile noma izinto ezizinzile ezimaphakathi nendawo evundlile ezansi kwengxenye ngayinye (okuhlanganisa nama-partitions angaguquki kanye nama-partitions avulekile) ukuze amanzi angena eminyango namafasitela akwazi ukuphuma ngaphandle.

Uma uhlaka olungaphandle oluseceleni kanye ne-fan sealing strip ifakiwe, izokwakha isikhala esivaliwe ngomugqa wokuvala omaphakathi, ongahambisani nokukhipha amanzi e-isobaric.

Uma ukhuluma nge-isobaric drainage, ungenza isilingo esincane: gcwalisa ibhodlela lamanzi amaminerali ngamanzi, ubhoboze izimbobo ezincane embotsheni yebhodlela, bese uphendulela ibhodlela phansi, kunzima ukuthi amanzi aphume kulezi zimbobo ezincane, bese siphinda senze izimbobo ezincane ezansi ebhodleleni, futhi amanzi angaphuma kalula ngezimbobo ezincane ebhodleleni.

Lesi futhi isimiso esiyisisekelo sokudonswa kwe-isobaric kweminyango namafasitela.

Kulungile, ake senze isifinyezo

Imichilo yokubeka uphawu ingenye yezinto ezibaluleke kakhulu zomnyango kanye nezesekeli zefasitela, ezisetshenziswa kakhulu kubalandeli befreyimu, ingilazi yefreyimu nezinye izingxenye, idlala indima yokuvala, ukuvimbela amanzi, ukuvala umsindo, ukumuncwa ukushaqeka, ukugcinwa kokushisa, njll.

Imichilo yokuvala ingahlukaniswa ibe yimichilo yempahla eyodwa kanye namapheshana ezinto ezihlanganisiwe ngokuya ngempahla. Njengamanje, imichilo yokuvala evame ukusetshenziswa emkhakheni weminyango namafasitela ihlanganisa imichilo yokuvalwa kwe-EPDM, imichilo yokuvala irabha ye-silicone (MVQ), imichilo ye-thermoplastic vulcanized (TPV), imichilo ye-polyvinyl chloride (PVC), njll.

Imichilo yokuvala ingahlukaniswa ngohlobo lokucindezelwa, uhlobo lokungena, kanye nohlobo lokunamathela ngokuya ngendlela yokufaka. Ngokwendawo yokufaka iminyango namafasitela, ingahlukaniswa ibe yimichilo yokuvala i-frame-sash, imichilo yokuvala ingilazi yefreyimu, kanye nemicu yokuvala ephakathi.

Ingabe kungcono ukusebenzisa imichilo yokuvala noma ama-sealant phakathi kwamafreyimu nezingilazi? Ngokuphathelene nokulawulwa kwekhwalithi yokwakha kanye nokuphepha kokwakhiwa kwendawo, umbhali uncoma ukusebenzisa ama-seal strips esikhundleni se-sealants esizeni.

Xhumana nathi

Mob/Whatsapp/We Chat:+86 13556890771(Direct Line)

Email: daniel.xu@aluminum-artist.com

Iwebhusayithi: www.aluminium-artist.com

Ikheli: Pingguo Industrial Zone, Baise City, Guangxi, China

Isikhathi sokuthumela: Nov-09-2024