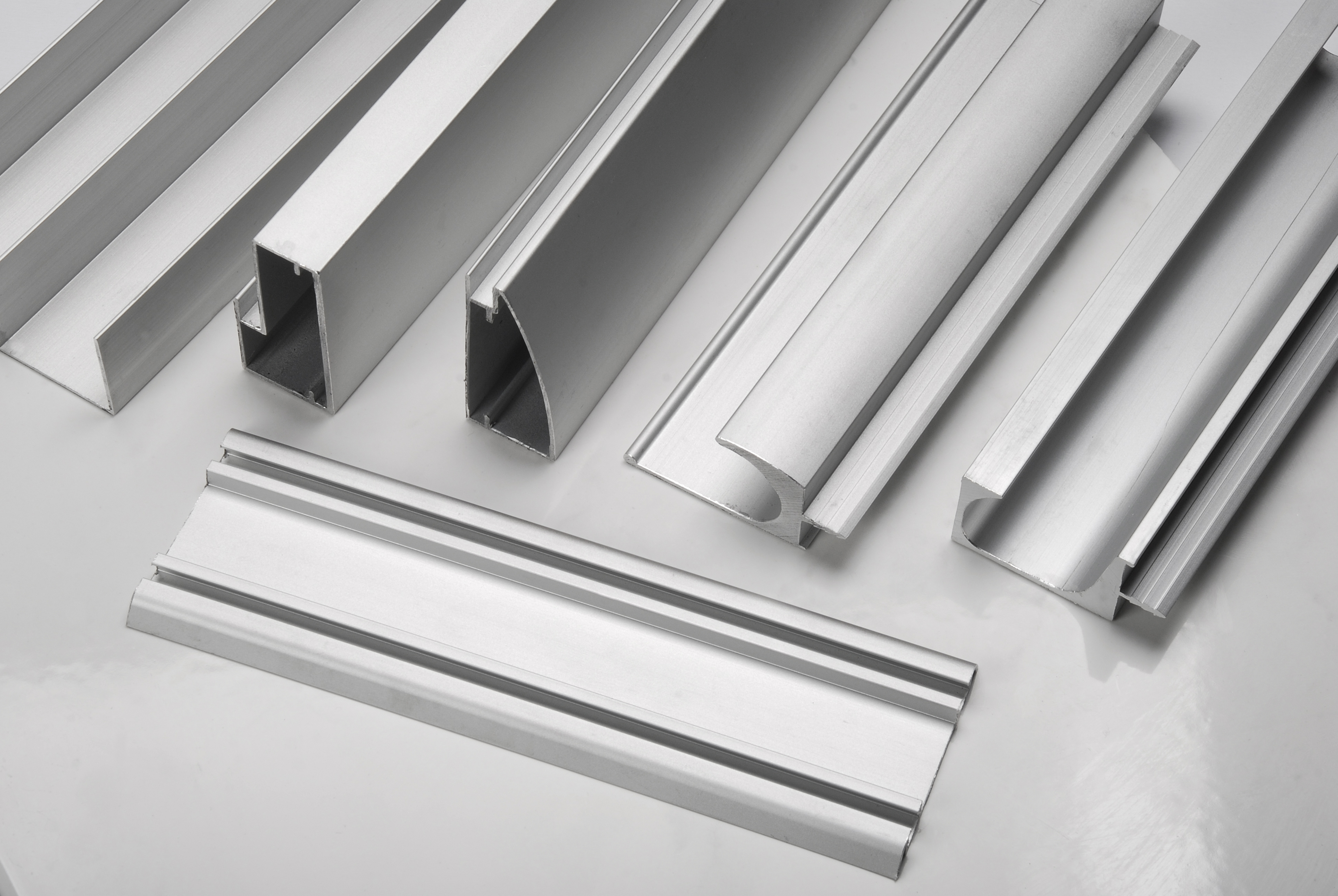

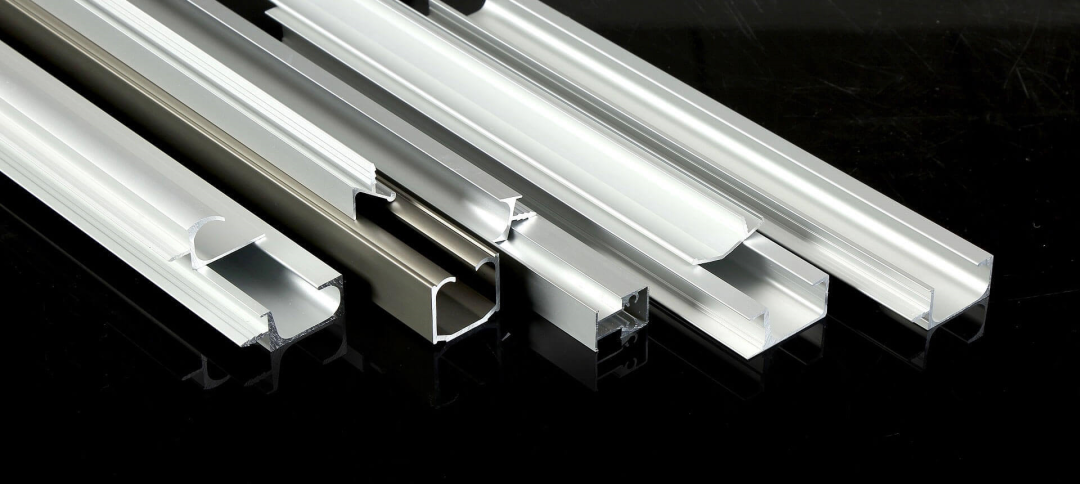

I-aluminium iyinto ebalulekile eyisisekelo. Empilweni yansuku zonke, sivame ukubona ukusetshenziswa kwamaphrofayili e-aluminium ekwakheni iminyango,amafasitela, izindonga zamakhethini, imihlobiso yangaphakathi nangaphandle kanye nezakhiwo zokwakha.

Amaphrofayili e-aluminium yezakhiwo anezidingo eziqondile zokumisa kanye nokukhiqizwa ngobuningi, futhi inqubo ye-aluminium rod extrusion ivame ukusetshenziselwa ukuzuza isisombululo esilungiselelwe ukukhiqiza nokukhiqiza. Umqondo oyisisekelo wokukhipha iphrofayili ye-aluminium ukufaka ingcindezi ethile entweni ye-aluminium emgqonyeni we-extrusion ukwenza ingxubevange ye-aluminium igeleze iphume emgodini othize wokufa, ngaleyo ndlela kutholwe amaphrofayili e-aluminium anomumo nosayizi othize. Le ndlela yokucubungula i-extrusion inezindleko eziphansi, ukusebenza kahle okuphezulu nokusebenza okulula, futhi ithatha ingxenye enkulu ohlelweni lwesimanje lokukhiqiza izimboni. Lesi sihloko sizogxila enqubweni yokukhiqiza i-extrusion yamaphrofayili e-aluminium, okusivumela ukuba sibe nokuqonda okujulile kwemikhiqizo yephrofayili ye-aluminium:

1. Ukukhiqizwa kwezinto ezingavuthiwe

Ngokwesilinganiso esibaliwe sokubunjwa kwamaphrofayili e-aluminium adingekayo, izinto ezisetshenziswayo ezihlukahlukene zihlonyiswe ngokufanelekile.Ingot ye-aluminium ishiselwa ezingeni elithile lokushisa ukuze incibilike, futhi inani elithile lezinto ezihlanganisiwe zengezwa oketshezini oluncibilikisiwe lwe-aluminium (i-magnesium ne-silicon ngokuvamile yengezwa emigqeni yomkhiqizo womnyango kanye newindi). I-slag ne-waste gas ekuncibilikeni kususwa ngezindlela ezihambisanayo zokucwenga.Ngaphansi kwezimo zenqubo yokuphonsa efanelekayo, uketshezi lwe-aluminium oluncibilikisiwe luthululelwa emshinini wokuphonsa, lupholile futhi luphonswe ezindongeni eziyindilinga eziphonswe ngamadamitha kanye nokucaciswa okuhlangabezana nokulindelwe.

①Beka izinti ze-aluminium zibe phansi endaweni yokubeka izinto, gwema ukusondelana kakhulu noma uzipakishe, futhi ubeke indawo ephephile yokusebenza ukuze uvimbele izinti ze-aluminium ukuthi zingagingqiki noma ziwe.

②Shisisa induku ye-aluminium kanye nesikhunta esithandweni ukuze ukhuphule izinga lokushisa libe ngu-480°C, futhi ukugcine kufudumele ihora elingu-1 ngaphambi kokucubungula okulandelayo;

③Beka isikhunta kusizinda se-die of extruder, faka induku ye-aluminium endaweni yokuphakelayo ye-extruder bese ulungiselela ukukhishwa;

④Iphrofayili ekhishiwe iphuma embobeni yokukhipha, futhi ikhanda lempahla lidonswa ugandaganda, futhi ukusika kokuqala kwenziwa ngokuya ngobude nosayizi obekiwe.

3. Ukuqondisa

Amaphrofayili e-aluminium adwetshwe yi-extrusion ngokuvamile awahlangabezani nezindinganiso zokuqondisa, okuthinta ukusetshenziswa okulandelayo noma ukusebenza kwemishini yemishini.Amaphrofayili e-aluminium extruded athunyelwa etafuleni lokuqondisa ukuze aqondiswe, bese ehanjiswa endaweni yomkhiqizo ophelile ukuze asikwe ubude.

4. Ukwelashwa ngesikhathi

Ukubeka impahla yephrofayili ye-aluminium alloy esithandweni sokuguga ukuze uyishise ekushiseni okuthile futhi uyigcine ifudumele amahora angu-2-3 ingathuthukisa kakhulu izakhiwo zemishini yephrofayili ye-aluminium alloy, ikakhulukazi izakhiwo zokuqina.Faka amaphrofayili e-aluminium anqunyiwe kuhlaka lwezinto ezibonakalayo, uwahambise endaweni yokuguga, bese ufaka esithandweni sokuguga ukuze uthole ukwelashwa kokuguga. Lapho izinga lokushisa lokuguga lifinyelela ku-200℃, ligcine lifudumele amahora angu-2, bese ulinda ukuthi likhishwe;Ngemva kokuguga sekuqediwe, lingakhishwa kuhhavini futhi lingene esigabeni sokupholisa. Ingapholiswa ngokwemvelo noma ngokwenziwa nge-cooler yomoya.Kuleli qophelo, umsebenzi we-extrusion uyaphela, futhi ukukhishwa kwamaphrofayili e-aluminium anekhwalithi efanelekile yokubukeka kanye nokuma nosayizi kuqediwe.

5. Ukwelashwa kwendawo

Sebenzisa ukwelashwa kwendawo efanele njengoba kudingeka. Njengamanje, kunezinqubo eziningana ezithandwayo zokwelashwa kwendawo embonini yomnyango kanye newindi: i-anodizing, i-electrophoresis, i-porcelain coating, i-fluorocarbon spraying, njll.

Xhumana no us ukuze uthole eminye imibuzo.

Ucingo/WhatsApp: +86 17688923299

E-mail: aisling.huang@aluminum-artist.com

Isikhathi sokuthumela: Aug-31-2023