I-Aluminium extrusion iyinqubo yokukhiqiza esebenza kahle kakhulu futhi eguquguqukayo esetshenziselwa ukwakha izingxenye ezinamaphrofayili athile ahlukene. Enhliziyweni yale nqubo kukhona enye yezinto ezibaluleke kakhulu:i-extrusion iyafa. Leli thuluzi elibunjwe ngokunemba libumba i-aluminium ngaphansi kwengcindezi enkulu futhi lidlala indima ebalulekile ekunqumeni ikhwalithi yomkhiqizo, ukuphela kwendawo, nokunemba kobukhulu.

Iyini i-Aluminium Extrusion Die?

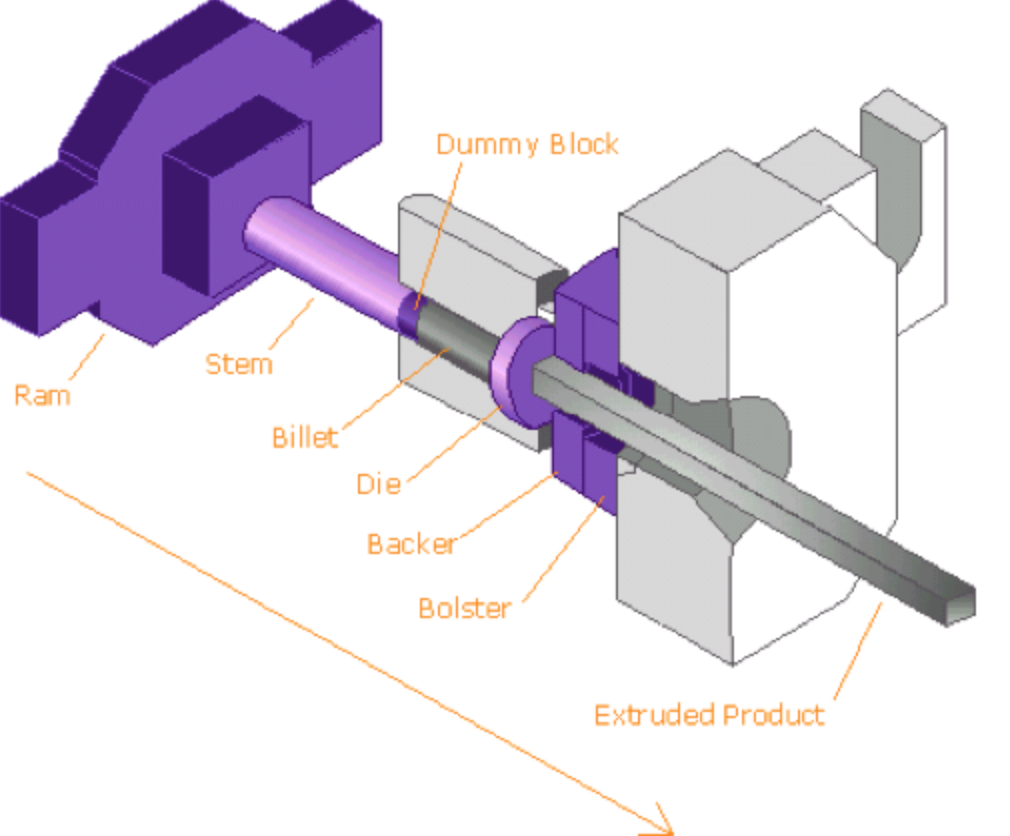

I-extrusion die iyithuluzi lensimbi eliklanywe ngokukhethekile elinento ethilekufa ukuvulalokho kubumba i-aluminium njengoba iphoqwa ngaphansi kwengcindezi ephezulu. Kanye namathuluzi okusekela afana nama-backers, ama-bolster, nama-sub-bolster, i-die iqinisekisa ukuqondanisa okufanele kanye nobuqotho besakhiwo ngesikhathi sokukhipha.

Izinhlobo ze-Extrusion ziyafa

I-Extrusion dies ihlukaniswa ngezinhlobo ezintathu eziyinhloko ngokusekelwe ku-geometry yephrofayela oyifunayo:

1. I-Solid Dies

Isetshenziselwa ukukhiqiza amaphrofayili ngaphandle kwanoma yimaphi ama-cavities - njengama-bar, ama-engeli, noma amashaneli.

● Izingxenye:

○ I-Die Plate: Iqukethe i-orifice emise okwephrofayili yokugcina.

○I-Backer Plate: Inikeza ukwesekwa ngemuva kwefa.

○Ipuleti lokuphakelayo (ongakukhetha): Isiza ekuqondiseni ukuhamba kwezinto.

2. I-Hollow Ifa

Idizayinelwe amaphrofayili ane-voids yangaphakathi njengamashubhu noma amafreyimu ewindi.

●Izingxenye:

○I-Mandrel (noma core): Yakha ingaphakathi langaphakathi.

○I-Die Cap: Yakha ijamo langaphandle futhi ibambe i-mandrel endaweni.

○Umsekeli: Inikeza ukwesekwa kwesakhiwo nokuphathwa kokushisa.

3. I-Semi-Hollow iyafa

Isetshenziselwa amaphrofayili ane-voids evaleke kancane — ukuhlanganisa izici zezingxenye eziqinile nezingenalutho. Lezi zilungele amajiyometri ayinkimbinkimbi anezindonga eziguquguqukayo.

Inqubo ye-Extrusion kanye nomsebenzi we-Die

Izinyathelo ezibalulekile ze-extrusion zihlanganisa:

1.I-Billet Preheating:

Amabhilidi e-Aluminium ashiswe kusengaphambili aze afike ku-370–500°C (700–930°F) ukuze kuthuthukiswe ipulasitiki.

2.Iyalayisha & Extrusion:

I-billet ilayishwa esitsheni, futhi inqama ye-hydraulic (enengcindezi evela kumathani ayi-1,000 kuya ku-15,000) iyiphusha idayisi.

3.Ukwakhiwa Kwephrofayela:

I-aluminium ithatha isimo sokuvula idayizi njengoba iphuma, yenze iphrofayili edingekayo.

4.Ukupholisa, Ukusika & Ukuqeda:

Amaphrofayili ayapholiswa, anwetshwe, asikwe ngobude, futhi angase aqedelwe phezulu njenge-anodizing noma i-powder coating.

Kuyo yonke le nqubo,i-die iqinisekisa ukunemba komumo, ikhwalithi ephezulu, nokungaguquguquki.

Ukubekezelela Okuhlobene Nokufa kanye Nokulawula Ukuqina Kwezindonga

Ukunemba kubalulekile. Ukubekezelelwa kwe-aluminium extrusion kuncike kulokhu:

●Usayizi wephrofayela nokuba yinkimbinkimbi

●Ukujiya kodonga(izindonga ezincane kakhulu zandisa ubunzima)

●Ifa gqoka ngokuhamba kwesikhathi

●Ukujiya kodongazingahluka kancane, ikakhulukazi kuma-dies amasha - ama-extrusions okuqala angase abe mncane kancane, kodwa ngokusetshenziswa, i-dies stabiling futhi ivumelane kangcono nomklamo wezinga. Kungakhoamaqoqo alandelayongokuvamile ikhombisa imiphumela eminyene futhi engaguquguquki.

Ukubekezelelana okuvamile kulawulwa izindinganiso zamazwe ngamazwe ezifanaEN 755-9nomaI-AA (Aluminium Association)imininingwane.

Ukwelashwa Kwe-Die Surface kanye Nokugcinwa

Ukuze kuthuthukiswe ukusebenza nokuphila, i-extrusion iyafa ngokuvamile:

I-Nitriding

Inqubo yokuqina kwendawo esakaza i-nitrogen endaweni efayo, okwandisa ubulukhuni nokumelana nokuguga - kubalulekile ekubambeni umfutho ophezulu kanye nezinga lokushisa.

I-Die Preheating (I-Die Cooking)

Obeye aziwe njengo "煲模(babo)” ngesiShayina, lo mkhuba ushisisa kancane kancane i-die ngaphambi kokuyikhipha ukuze kuncishiswe ukushaqeka okushisayo futhi kuthuthukiswe ukugeleza kwensimbi.

Izinselelo Ezivamile Zokufa kanye Nemikhuba Yokuvimbela

✅ Ukuguga nokukhala

Ukucindezela okuphezulu nezinga lokushisa kubangela ukuguga kancane kancane.Ukuhlola okuvamile, ukupholishwa kabusha, nokuphinda kufakwe i-nitridingandise impilo yokufa.

✅ Ukukhubazeka kobuso

Ukuklwebheka, imigqa yokufa, noma ukwakheka kungathinta ikhwalithi yendawo. Umjikelezoukuhlanza ukufafuthizokwelapha ebusweniukusiza ukunciphisa amaphutha.

✅ Ukuphathwa Kwezishisayo

Ukushisa okungalingani noma ukupholisa kuholela ekulimaleni noma ekuqhekekeni kokufa. I-insulation efanele kanye nokushisa okulawulwayo kubalulekile.

✅ Ukuqondanisa nokusekela

Ukuqondanisa okungalungile kubangela amaphutha e-dimensional kanye nokwehluleka kokufa ngaphambi kwesikhathi. Izikhathi ezithileukulinganisa kabushafuthiukugcinwazibalulekile ngokunemba.

Kungani Kufa Okubalulekile ku-Aluminium Extrusion

I-extrusion eklanywe kahle, enakekelwa kahle inomthelela oqondile:

●Ukunemba kobukhulu

●Ubunkimbinkimbi bephrofayela

●Isivinini sokukhipha

●Ukuqedwa kobuso

●Izindleko zomkhiqizo sezizonke kanye nokuvumelana

Ukukhetha uhlobo lokufa olulungile, ukuqonda ukuphathwa kokuqina kodonga, nokusebenzisa izinqubo zokuvikela eziqinile zokuvikela kubalulekile ukuze kuzuzwe imiphumela engaguquki, yekhwalithi ephezulu.

Ufuna Uzakwethu Othembekile Wokufa Nokwe-Extrusion?

E-[Igama Lenkampani Yakho], sisebenza ngokukhethekile ngokunemba kwe-aluminium extrusion futhi sinikezela ngokusekela okugcweleukuthuthukiswa kwe-custom die, ukulungiselelwa kwephrofayela, futhiukuphathwa komjikelezo wokuphila. Kungakhathaliseki ukuthi ukhiqiza amaphrofayela aqinile, angenalutho, noma ayingxubevange eyinkimbinkimbi, ithimba lethu lonjiniyela lilungele ukusiza ngemininingwane yochwepheshe kanye nokukhiqiza okuthembekile.

Xhumana nathi namuhlaukuze ufunde kabanzi mayelana nokuthi singenza kanjani imiklamo yakho iphile ngezixazululo ezifanele ze-extrusion.

I-imeyili: will.liu@i-aluminium-artist.com

Iwebhusayithi: www.i-aluminium-artist.com

Ikheli:IPingguo Industrial Zone, Baise City, Guangxi, China

Isikhathi sokuthumela: Jun-17-2025